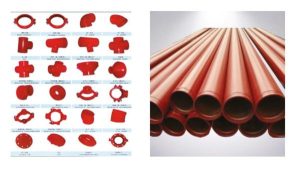

Pipe fitting is the occupation of installing or repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials. This work involves selecting and preparing pipe or tubing, joining it together by various means, and the location and repair of leaks.

Pipe fitting work is done in many different trades: oil & gas, firefighting, Plumbing, HVAC, manufacturing, fire prevention, and many others. Fitters work with a variety of pipe and tubing materials including several types of plastic, copper, steel, iron, aluminum, clay, and lead.

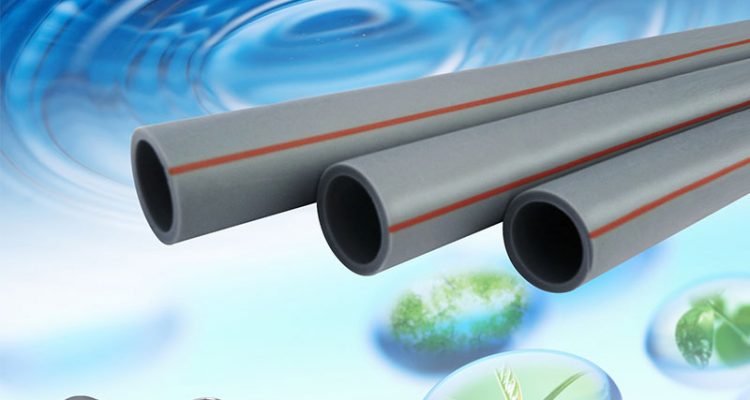

HDPE piping is performed in two ways i.e. Heat Fusion & Electro Fusion.

Heat Fusion

Heat fusion (sometimes called heat welding, butt welding or simply fusion) is a welding process used to join two different pieces of a thermoplastic. This process involves heating both pieces simultaneously and pressing them together. The two pieces then cool together and form a permanent bond. When done properly, the two pieces become indistinguishable from each other. Dissimilar plastics can result in improper bonding.

This process is commonly used in plastic pressure pipe systems to join a pipe and fitting together, or to join a length of pipe directly to another length of pipe. Generally, polyolefin (such as polypropylene, polyethylene, and polybutylene) are used for these applications.

But welding is usually performed using one of several methods. The first, and most common, is butt welding or butt fusion, which is a type of hot plate welding. This technique involves heating two planed surfaces of thermoplastic material (typically polyethylene) against a heated surface. After a specified amount of time, the heating plate is removed and the two pieces are pressed together and allowed to cool under pressure, forming the desired bond. Butt welding outside of manufacturing is usually performed to join pipes.

Electro Fusion

Electro fusion is a method of joining MDPE, HDPE and other plastic pipes using special fittings that have built-in electric heating elements which are used to weld the joint together. The pipes to be joined are cleaned, inserted into the electro fusion fitting (with a temporary clamp if required) and a voltage (typically 40V) is applied for a fixed time depending on the fitting in use. The built in heater coils then melt the inside of the fitting and the outside of the pipe wall, which weld together producing a very strong homogeneous joint. The assembly is then left to cool for a specified time.